Are you crazy about color? Is brighter, BETTER? I think so. I would like to introduce to you some really great and really bright fluorescent pigments. You can add them to your castings to make them glow under UV lights.

Ignite colorant's can be added to any Smooth-On liquid urethane rubbers, plastics, foams (rigid and flexible) and silicones. The fluorescent or the glow effect will be maximized by the use of UV light or a black light.

They are available to you in a 9 pack sampler which will include @ $29.76

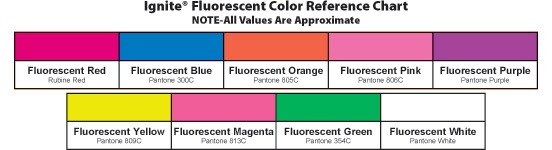

RED-YELLOW-GREEN-PINK-BLUE-ORANGE-WHITE-MAGENTA(more of a hot pink)-PURPLE

Colors are blend able to make custom colors to suite your pallet. Colorant is to be added to the Part B side.

They are also available in 4oz size @ $14.57 each

If you are looking for a larger size( 1 gallon or 5 gallon) they are available upon request, you just need to give us a call here at the office (631) 920-5079.

There are 2 ways that you can add the color you your cast:

Volume (measured drops) :

Add 30 drops of ignite per 3 oz (88ml) of mixed material. If you are using a translucent material (smooth-cast 325) you can use 15 drops to maintain translucency

Weight (gram scale required) :

Add colorant at a ratio of between 0.5%-1.5% of the total weight (part A &B mixed) of the material being cast. 1% pigment yields the best results.

MORE THEN 1.5% BY WEIGHT OFFERS NO BENEFIT AND IS A WATE OF COLORANT. TOO MUCH COLORANT MAY CAUSE INHABITION.